MORE COMPETITIVE AND MORE SUSTAINABLE

For us, there is a daily exercise of seeking results based on innovation, safety and sustainability in order to provide high quality cellulose and strategically manage our business.

RESPONSIBLE USE OF NATURAL RESOURCES

We are committed to improving our environmental performance. Since Veracel is a company guided by modern environmental technologies and cellulose manufacturing process, the efforts to improve performance is challenging, however, but seen as always possible. This is the case with waste management. We have reported a 99% average of recycled waste in recent years.

In addition, we have kept our 22.3 m³ record of water consumption to produce one ton of cellulose. These initiatives are already proving successful. We expect to stabilize processes, make new improvements and continuously evolve in the results.

SUSTAINABLE ENERGY SOURCE

We have the continuous challenge of being more and more efficient in energy generation, while consuming energy responsibly. The partnership with an ethanol production plant, next to the Veracel site, is great for both companies. The burning of sugarcane pulp in an auxiliary boiler has become a great deal, transforming potentially polluting waste into an electric power generation source.

HOW WE PRODUCE OUR CELLULOSE

SEEDLING NURSERY

EUCALYPTUS PLANTING

HARVEST

WOOD TRANSPORT

FACTORY

FROM BAHIA TO THE WORLD

SUSTAINABLE FOREST PRACTICES

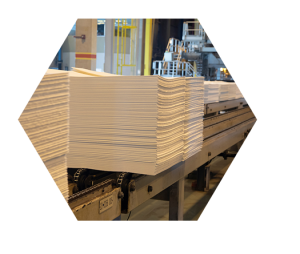

INDUSTRIAL PRODUCTION WITH HIGH EFFICIENCY AND QUALITY

The eucalyptus wood is taken to the factory. After being washed, it is cut into chips (small pieces of wood) that pass through sieves to separate fractions that do not go to the cooking process. These fractions are placed in the biomass pile to be used in the steam and energy production and supply the factory. The selected chips go to cooking in the digester. At the end, we have brown colored pulp that goes on to the washing, bleaching and drying process to remove excess water. After drying, they are cut and packaged for transport.

PULP FROM BAHIA TO THE WORLD

The Veracel pulp production is transported in trucks to the Belmonte Maritime Terminal, which is 60 km away from the factory. From there, it travels on barges to Portocel in the state of Espírito Santo and then to different factories abroad.

WE GO BETTER BY SEA

Transporting our cellulose by barge means a sustainable choice with lower carbon emissions and less cargo vehicles along the BR101 highway in the Bahia-Espírito Santo stretch.

In continuous working mode, teams and crews take turns, operating 24 hours a day. While a barge is loaded in Belmonte, another one is on coastal navigation along the coast of the region. At the same time, a third one is unloaded in Barra do Riacho (Espírito Santo) and, upon arriving at the terminal, the tug boat is uncoupled from one barge and coupled to another, starting the return trip.

The barges have now a thermal camera whose objective is recording the movements of whales and small boats. The images are read by a software that emits different audible alarms when identifying any obstacle in front of the barge within a radius of up to two kilometers. That’s safety at sea!

JUBARTE WHALE: FROM BAHIA BY NATURE!

The population of Jubarte whales in the waters of southern Bahia has grown, and Veracel monitors and conserves these wonderful giants.

These whales visit the coast of Bahia in June-November for reproduction. We have made this nursery chosen by them an even safer place. During this period, they come to Bahia to mate and then return to the south pole. After 11 months, they come back to give birth and breastfeed their babies.